Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Improving laser powder-bed fusion processes using synchrotron X-rays

Laser-powder bed fusion is an advanced additive manufacturing technology for producing small and precise metal components. The gas company Linde and Chalmers University of Technology used synchrotron X-rays to study how to improve laser-powder bed fusion processes by looking at how helium influences the solidification of metal materials.

In laser-powder bed fusion (L-PBF), a high-power laser beam is scanned over a metal powder bed, sintering the powder into the required shape as it moves. Additional powder is added, and the laser beam builds up the desired component, layer by layer. This technique is suitable for producing small and precise components. The process commonly incorporates titanium, stainless steel, maraging steel, aluminium, cobalt chrome, nickel alloy, and Inconel.

Research studies indicate that using helium and its mixtures as processing gas can improve process stability. It can also reduce the generation of spatters, a by-product that leads to defects in LPBF-processed components and powder degradation.

Until now, it has not been known how using helium influences metal material solidification and the resulting component properties. The lack of knowledge has hindered the development and implementation of gas solutions. The gas company Linde set out to change this with the help of synchrotron X-rays.

Combining X-ray research techniques to gain novel insights

A research team from Linde and the Chalmers University of Technology visited the Swiss Light Source synchrotron at the Paul Scherrer Institute (PSI) in Switzerland to perform part of the experiment at the Micro XAS beamline.

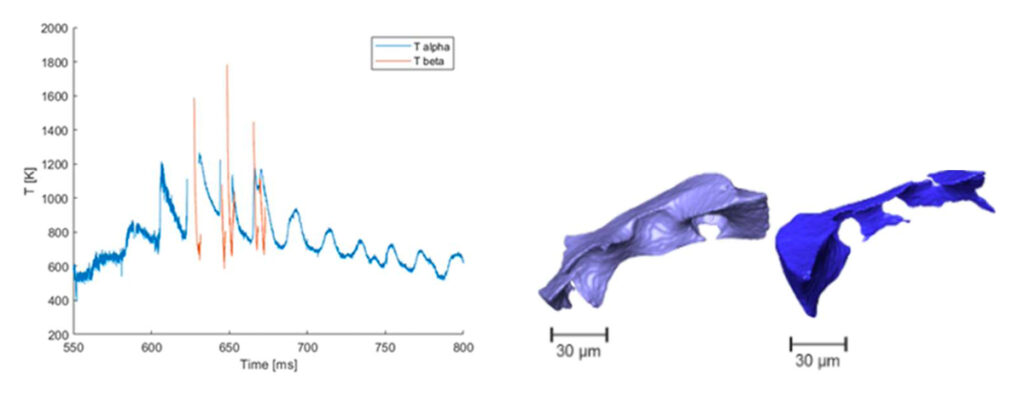

Using the test rig designed by PSI, the team studied various gases, including argon and helium and their mixtures, using in-situ X-ray Diffraction analysis (XRD). This research technique allows for studying the effects of the gas on the LPBF process stability by depicting the kinetics of the phase transformation.

The team also performed X-ray Computed Tomography measurements on the LPBF fabricated samples using the BAMline at BESSY II synchrotron in Berlin, Germany. This allowed them to distinguish the porosity distribution in as-printed samples at high resolution and measure residual stresses. The work was associated with the Federal Institute for Materials Research and Testing (BAM).

Helium improves LPBF process stability and decreases spatter

The measurements showed that using helium improved LPBF process stability compared to using only argon, which is the standard. Helium also allowed slightly higher cooling rates.

Furthermore, the generation of spatter by-product decreased with the samples with helium, resulting in improved powder reusability. There were no additional residual stresses in the built part of the components, and pore distribution and characteristics were comparable between different gases.

Towards improved gas solutions for LPBF processes

These insights have given Linde a better understanding of the effect of helium on the process and contributed to the company’s further development of gas solutions. The company has discovered cutting-edge possibilities for monitoring and characterising the LPBF process as well as the produced component using large-scale facilities.

In the future, these results can further support the development of significantly improved LPBF processes.

Contact Partners

Case Details

Linde

Chalmers Industriteknik