Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Investigating tablets

Magle Chemoswed is a Malmö-based contract development and manufacturing organization that supports companies in the pharmaceutical and medical device industry. In collaboration with SmiLe Incubator and MAX IV Laboratory they have explored the use of synchrotron powder diffraction to find answers to a challenging customer request.

Optimizing pharmaceutical manufacturing

When manufacturing a pharmaceutical product, the active pharmaceutical ingredient (API) can frequently exist in different crystalline forms other than the desired one, so called polymorphs. In order to optimize the manufacturing process there is a need to accurately measure the amount of wanted and unwanted polymorphs, even at very low concentrations, in the final product. X-ray powder diffraction XRD Used for atomic structure determination of materials, e.g. pharmaceuticals, catalysts, battery materials, and proteins.More info diffraction is a technique that can be applied to perform such measurements. MagleChemoswed has both extensive experience and in-house capabilities to perform such determinations.

Lost in the noise

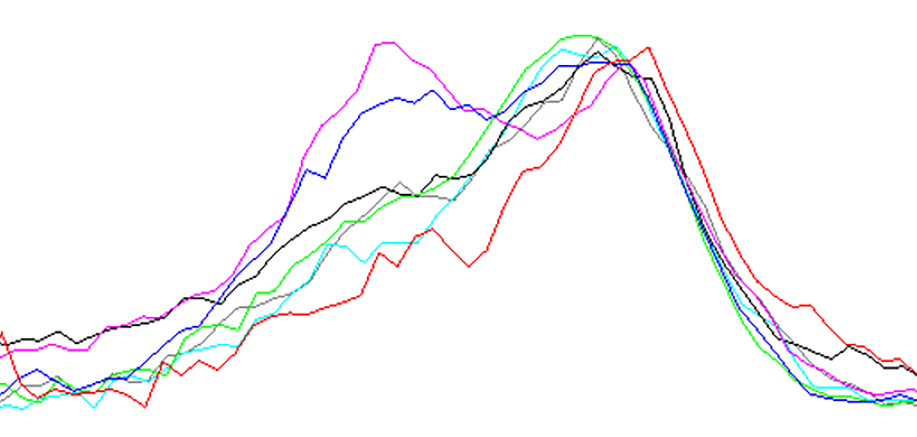

In lab scale equipment the detection limit pose a challenge with samples with very low concentrations of the API. It is increasingly difficult to detect the different polymorphs with lab-scale X-ray powder diffraction equipment at <30% concentrations of the active ingredient.

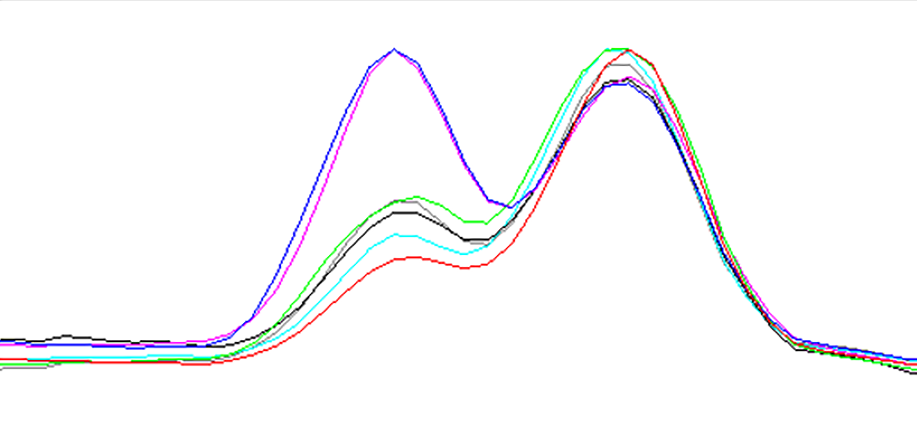

Considering that many pharmaceutical formulations have drug loads well below 10%, this is an important difference between lab scale equipment and large-scale research infrastructures such as the MAX IV synchrotron in Lund. Synchrotron based techniques can be especially useful in cases where you want to study fast processes or measure low concentrations in your sample. The DanMAX beamline at MAX IV has a powder diffraction instrument with fast and low-noise detection.

“Based on synchrotron data, the unwanted polymorph can be confirmed in all samples, and a clear ranking for all seven samples can be made.”

Martin Lindsjö, Magle Chemoswed

Different tools for the job

After running the experiment at DanMAX, on powdered material from the tablets, it was clear that the signal-to-noise, and consequently the detection capabilities at DanMAX, differed significantly from the company’s in-house laboratory XRPD equipment. The obtained results provided the research team at Magle Chemoswed with significantly greater insight and accuracy regarding the distribution of polymorphs in the tablets and then ultimately the ability to supply the customer with conclusive results

Comparing processes

Besides the specific client question of relative concentrations of API polymorphs in the tablet samples, Magle Chemoswed also learnt how their own in-house XRPD equipment compare to MAX IV and the DanMAX beamline. With this knowledge they can now better tailor their offers to future customers and will be able to include hitherto unattainable levels of accuracy and detectability when needed.

This experiment and process was made possible by the project, MAXESS Industriarena, a regional project co-funded by the European Regional Development Fund and the Region of Skåne.

Contact Partners

Case Details

MagleChemoswed

Smile IncubatorDanMAX