Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Solving the crystal structure of novel complex materials

The company FAMAR conducted high resolution X-ray diffraction experiments for structural analysis of novel catalysts at the synchrotron facility PETRA III at DESY. With its new complex materials FAMAR aims to reduce C02 emissions in industry.

Developing catalysts for greener chemistry

Important challenges of the 21st century include the reduction of CO2 emissions to combat climate change, as well as the development of new materials for hydrogen storage for future energy technologies. The Polish chemical company FAMAR in Dankowice produces chemical catalysts for industrial processes which limit the emission of harmful gases and also are useful for storage of gases.

New ways to measure crystal structures

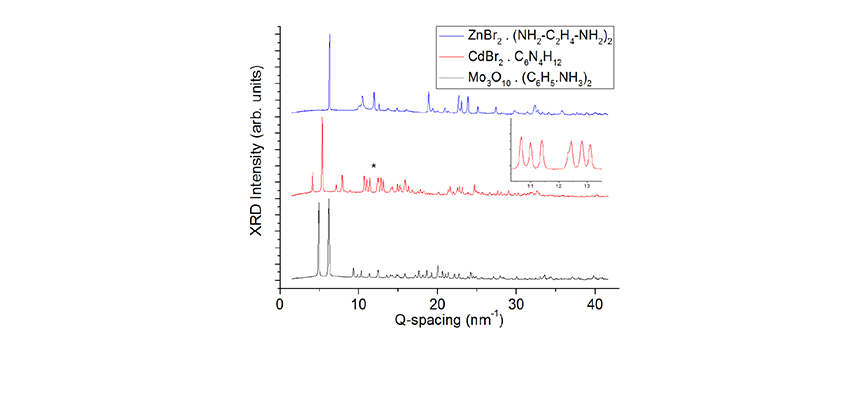

To understand the crystal structure of these novel materials, a study by FAMAR enabled the performance of high resolution X-ray Diffraction (XRD) at the P02 beamline at DESY in Hamburg. XRD is a technique used to measure the crystal structure of ordered materials – and information about the space groups, lattice constants and atomic positions can be extracted.

Revealing hidden peaks

The measurements have been instrumental in solving the crystal structure of many complex materials, and many features of the measured diffraction patterns were superior to those measured using conventional laboratory diffractometers. Some peaks which are very close together and would usually overlap were made distinguishable with the synchrotron source, as well as crystal phases which were present in a mixture of amorphous phases which are undetectable with conventional sources.

One step closer with synchrotron radiation

The XRD technique and especially the setup at the Beamline P02 allowed FAMAR to get the full structural information of their catalyst. Due to the high x-ray energy and hence superb resolution, structural information was revealed that was formerly hidden in lab-based experiments. With this knowledge FAMAR is one step closer to produce new catalysts for greener chemistry.

Contact Partners

Case Details

Famar

Powder Diffraction and Total Scattering Beamline P02.1