Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

A large collaboration to improve duplex stainless steel

A group of representatives from academia, research institutes, and steel manufacturers and users, used synchrotron light to study duplex stainless steel. They successfully gathered information that can help improving the resistance and lifespan of this material.

Make a great material better

The term duplex stainless steel describes a family of steels with exceptional resistance to corrosion and with high mechanical strength. These features make duplex stainless steel a very convenient material for the production of light, compact, and high-resistance components. In the attempt to understand and improve the composition of duplex stainless steels, a group of researchers from academia, research institutes, steel manufacturers, and steel users joined forces. The results they obtained by performing synchrotron X-ray scattering techniques have a direct impact on duplex stainless steel manufacturing companies and help them improve the steel production process.

Avoid precipitates

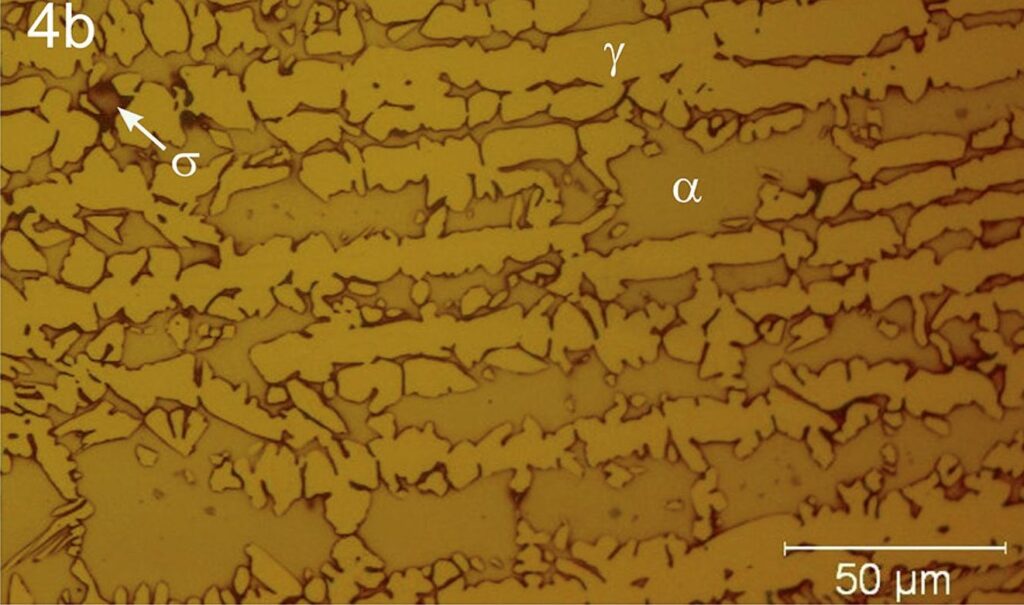

Duplex stainless steel is often affected by the presence of precipitates and intermetallic phases that accumulate in the structure after heat treatments or welding. These precipitates can compromise the performance of the material. Understanding the cause driving the formation of these precipitates and being able to follow the kinematics of their growth is of great interest for both manufacturing companies aiming to optimise the production process, and material user companies wanting to enhance the application of the steel and prolong their products’ lifetime.

This project saw the collaboration of many partners like the Royal Institute of Technology in Stockholm (KTH), the metals research institute Swerim, the steel manufacturers Sandvik and Outokumpu, the material user Alfa Laval, and the staff from the Petra III synchrotron, where the experiments were performed. This rich collaboration promoted extensive discussion and sharing of ideas and resulted in increased knowledge and skills on synchrotron research for all partners.

Synchrotron light is the right tool

There are multiple benefits in studying the composition of stainless steel with synchrotron light. Researchers can use high-energy X-rays to follow the kinetics of phase transformation during relatively fast heating and cooling processes. This allows to replicate temperature conditions similar to those used in heat treatments and welding of steel, and to observe the formation of the intermetallic phases and precipitates. The team preformed in-situ Wide-Angle X-ray Scattering (WAXS) to observe the specimen during the phase transformation, and ex-situ Small-Angle X-ray Scattering (SAXS) to quantify the precipitates.

With the gathered evidence, the researchers assessed how exposing the steel samples to high temperatures altered the phase fractions and precipitated content. These results can now be used by the manufacturing companies to help predict the phase transformation in duplex stainless steel and improve the manufacturing of this material.

Contact Partners

Case Details

Outokumpu Stainless AB, Alfa Laval Tumba AB, AB Sandvik Materials Technology

SWERIM LSI group