Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Converting non-reactive biomass ash into environmentally friendly cement

Getting rid of an environmental and financial burden

The combustion of biomass for electricity and heat production is increasing worldwide, and consequently the amount of fly ash produced from biomass combustion is also growing. Disposal of ashes in a landfill is not only expensive, but also neglects the economic and environmental value the ashes still hold. There are two strategies to use the ashes: as fertilizer in agriculture and forestry or in civil construction. Renotech OY from Finland tries to go the second path and modify biomass ashes to obtain better cement that can be used in civil engineering and as fire protection material.

From pilot plant to industrial level production

Modification of the ashes is needed to assure that the produced cements have the needed compressive strengths to be used in civil engineering. The modification is done by mixing in additives into the biomass before or during the combustion process. Former trial runs showed a positive impact of additives on the cements compressive strengths. Unfortunately, the compressive strength is not sufficient yet and more insights into the mechanisms of the strength development are required to formulate a more concrete business concept.

Combined analysis methods

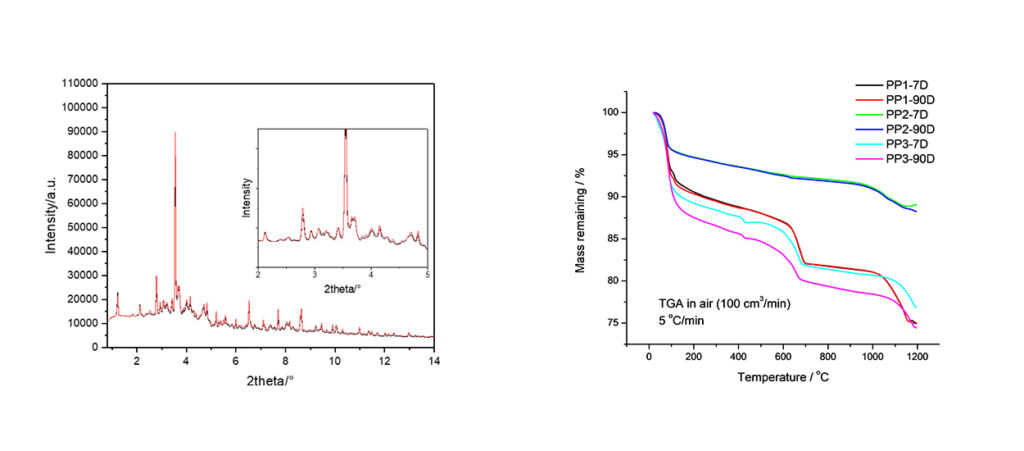

The research comprises of a thermogravimetric analysis, performed at the University of Turkulu, Finland, and synchrotron X-ray diffraction at the synchrotron facility PETRA III at DESY on three biomass ash cement samples in different hydration states. The thermogravimetric analyses gave a first insight in the composition of the phases in the different ashes. The X-ray powder diffraction measurements together with a Rietveld refinement of the diffraction results opened a deep insight in the composition of the different phases in the ashes. The results of the measurements helped the research and development of environmentally friendly cement by shading light upon the mechanisms of strength development during the ash modification trial runs.

Contact Partners

Case Details

Renotech OY

Powder Diffraction and Total Scattering Beamline P02.1