Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Developing more durable concrete using neutron and X-ray tomography

Concrete is the most widely used building material worldwide. To study what happens when concrete freezes, and is exposed to different types of moisture loads, Cementa AB, Malmö University, and Lund University used neutron and X-ray Tomography with the aim to develop concrete that is safer and more resistant to harsh weather conditions.

Neutron scattering and X-ray tomography are ideal techniques to use to study concrete. Neutron scattering can provide information about how water behaves within the concrete, whereas X-ray tomography can yield knowledge about heavier elements such as cement mortar, an ingredient in concrete.

In this case, the researchers examined and compared cement mortar samples exposed to different temperature cycles from room temperature to -13⁰C three times.

Comparing different temperatures and impacts on concrete

The cement mortar contained air entrainment agents, which are added to make them more durable to moisture during freeze-thaw cycles. These entrain microscopic air bubbles in cement compositions.

To conduct the experiment, the researchers used the D50 NeXT dual-modality neutron and X-ray tomography experimental station at Institut Laue Langevin (ILL), Grenoble.

Unique insights into concrete using X-rays and neutron tomography research techniques

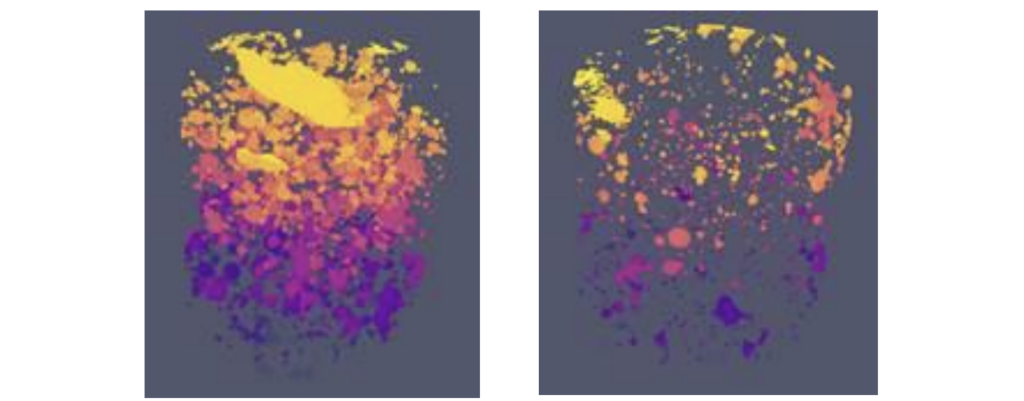

Using a combination of X-ray and neutron imaging, the researchers could distinguish between water-filled and air-filled pores within the cement mortar.

They were also able to examine individual air voids in the material and to follow how the degree of water saturation in those voids changed as the cement mortar froze and thawed.

Improving the efficiency of air-entraining agents in concrete

The project provided more knowledge about how dual-modality neutron and X-ray tomography can be used to study cement-based materials to produce more durable and sustainable concrete.

This technique can pave the way for new knowledge, e.g., about the interaction between new cement binders and air entrainment agents, and ultimately lead to the developing of new products.

“Having the opportunity to locate the water in cement-based materials during and after different types of loads is a fantastic opportunity to increase our knowledge about these materials, and a new opportunity to verify existing complex models. This is the path to more sustainable products. The fact that the industry is involved from the beginning shows their great interest in these questions and the willingness to explore new technologies to get answers.”

Katja Frid, Head of Department at Department of Materials Science and Applied Mathematics, Malmö University

Contact Partners

Case Details

Cementa AB

Division of Solid Mechanics – Jonas Engqvist