Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Discover the true potential of your biomaterial with X-rays

BoneSupport AB and scientists from Lund University used X-ray tomography to observe how the bone substitute produced by the company behaves inside the bone. They confirmed the distinctive features of the product and observed how it protects the bone material during mechanical loading.

A biomaterial to reinforce bones

BoneSupport AB develops biomaterials to be injected in bones and used as bone substitutes in patients. The company seeks to better understand how the biomaterial behaves and interacts with the bone during mechanical loading, and how the bone response is altered when combined with the biomaterial. Taking advantage of synchrotron X-ray’s high resolution, BoneSupport conducted experiments that showed an increased plasticity in samples where the bone is reinforced with their proprietary biomaterial. This evidence helps the company understand the features of the bone substitute once inside the bone and is valuable for future product development.

Filling the gaps

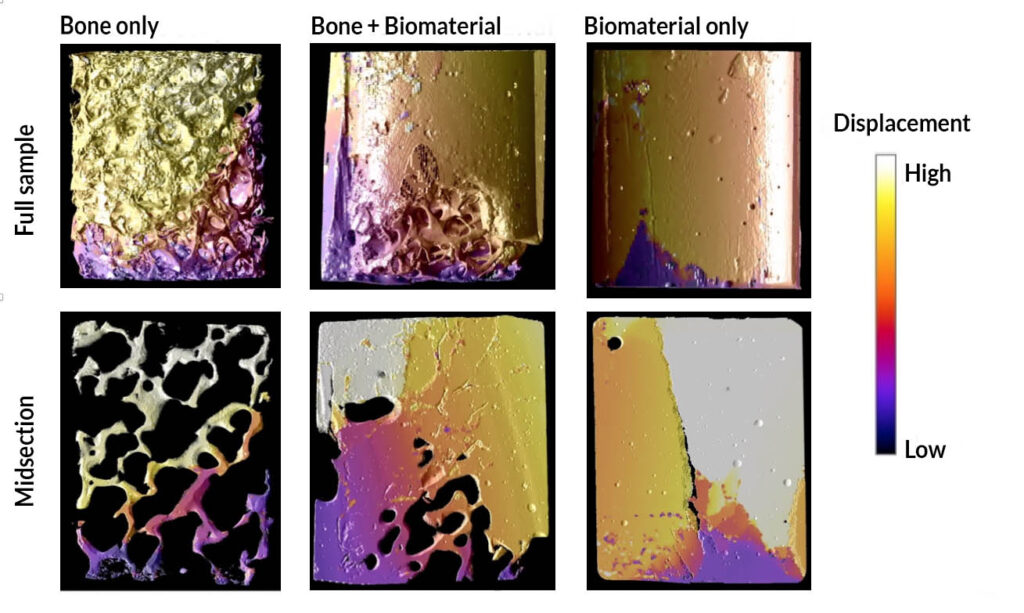

How does the biomaterial behave once injected in the bone? How does it interact with the native bone material? Does it improve the bone response to mechanical stress? Answering these questions involves understanding how the bone and the biomaterial interact during mechanical loading (which is the application of physical pressure to the point where the material fails). To tackle this challenging task, BoneSupport is collaborating with researchers at Lund University. The team turned to synchrotron-based X-ray tomography, which allowed them to carefully observe increasing stresses and their consequences in the biological structure. These experiments showed that the biomaterial produced by BoneSupport absorbs the loading in place of the native bone structure, thus helping the bone to better withstand mechanical stress.

The most powerful X-rays

The group of researchers from BoneSupport and Lund University aimed at understanding how differently a native bone and a composite of bone and biomaterial react to loading, where does the crack start, how does it propagate, and at what point does it fail. Synchrotron light is the only source of X-rays powerful enough to allow such experiments in a reasonable time frame, thanks to its higher resolution, better signal-to-noise ratio, and faster data acquisition rate. At the Swiss Light Source (PSI), the team performed high resolution tomography with in situ mechanical loading. They gathered a pool of human bone samples, injected half of it with the biomaterial, and left the other half in its native state.

The composite samples showed a more plastic behaviour, increased peak force, stiffness, and absorbed energy. The company also observed that the biomaterial seems to absorb most of the mechanical load leaving the bone largely intact until failure. The findings help BoneSupport understand how the biomaterial responds to loading inside human bone. This project also extended earlier collaborations between the company and Lund University to a new area of biomaterial characterisation.

Contact Partners

Case Details

BoneSupport AB

Lund Biomechanics