Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Enhanced cast iron for Scania’s vehicles

Scania together with Lund University and RISE used synchrotron light to gain deeper knowledge on how the cast iron elements used in their vehicles are subjected to stress that could lead to cracks. The gained knowledge is beneficial for both material R&D and product development activities, in the aim of developing improved cast iron components.

The toll of heavy transports

Scania is a world-leading provider of transport solutions, including trucks and buses for heavy transport applications. Their vehicles include several cast iron components that are subjected to stress that could potentially lead to fatigue damage and failure after repeated load cycles. Over time, the repeated loading and unloading of goods, materials, and people can cause the propagation of cracks in the cast iron elements, which contribute to fatigue damage. Using synchrotron light, experts from Scania advanced their understanding of how cracks propagate in cast iron, obtaining instrumental knowledge for both their material development and product development activities.

Cracks at the microscale

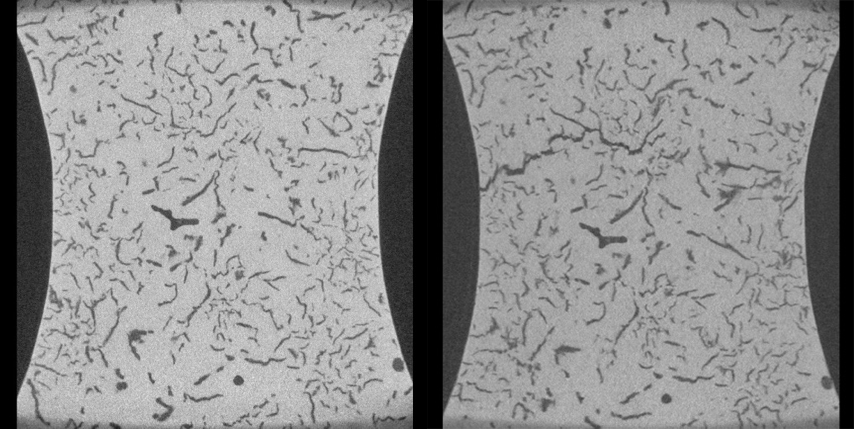

The occurrence of cracks in a component has a critical influence on its total lifespan. In order to better understand the mechanism of crack propagation, it is important to characterise the microstructure of cast iron and its composing elements, as they affect the way in which cracks propagate. Being able to predict if and how cracks generate and propagate based on the microstructure can help designing cast iron elements with improved resistance to fatigue. The use of synchrotron X-rays can allow researchers to achieve the desired high spatial and temporal resolution needed to study the cracks during fatigue load cycles.

Improving fatigue resistance

The project was led by a team of experts from Scania in collaboration with researchers from Lund University and RISE. Initial cracks generation and imaging was performed at RISE and at Lund University, while the synchrotron experiments were conducted at the Petra III synchrotron in Germany. The synchrotron experiments focused on 3D tomography imaging of fatigue crack evolution and of the microstructure of cast iron under mechanical load. The team took a total of 150 tomography images during stepwise loading (incremental loading according to the planned fatigue load cycles).

The researchers successfully monitored the behaviour and evolution of fatigue cracks and verified that synchrotron X-rays allow to observe the damage and deformation mechanisms taking place at different microstructural features. These results, which would not be achievable without the use of synchrotron light, are of note-worthy help for Scania’s material development and design of improved cast iron elements.

Contact Partners

Case Details

Scania CV AB

LSRI-initiative at RISESwedish Material Science Beamline P21