Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

High-resolution synchrotron XRD analysis for damage-tolerant bearing steel

Scatterin AB and Ovako AB teamed up to investigate the microstructure of bearing steel with PETRA III’s brilliant synchrotron light. Bearing is a widely used component, especially in vehicles and wind turbines, that involves moving as rolling parts. Even a minor weight reduction in the bearing would significantly reduce fuel consumption and CO2 emissions. The design of novel steel that allows the manufacture of more compact and lighter bearings requires a better understanding of steel microstructure exposed to cyclic loads.

2D mapping of dislocation density evolution

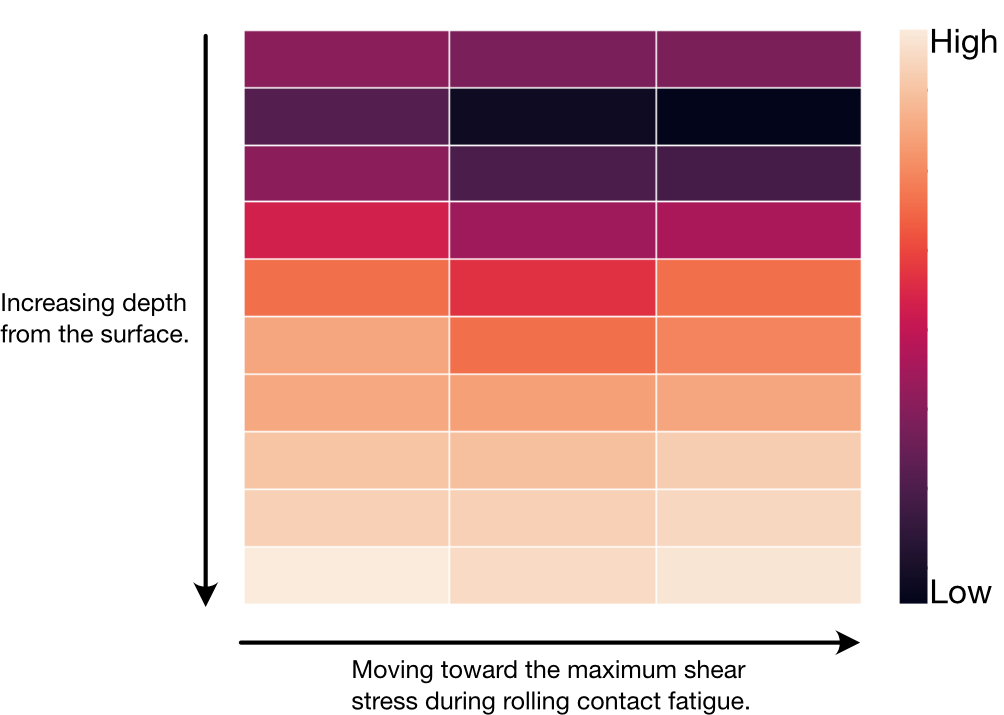

Bearings get exposed to cyclic loads due to rolling contacts while they operate. This exposition causes deterioration within the steel micro-structure. The detectable microstructural damages involve stress-induced martensite transformation, the formation of elongated ferrite microband, and white etching bands and lenticular cementite. Such microstructural changes lead to a lower hardness within the steel subsurface. Here, dislocation density is a critical parameter in affecting the microstructural evolution, and accordingly, the performance of a bearing. However, the investigation of dislocation density evolution in the steel subsurface by lab-scale X-ray diffraction (XRD), is unable to capture the local changes in the subsurface due to the large beam size and low penetration depth, hence only the near-surface information can be obtained.

revealed in μm resolution.

Reaching high spatial resolution with synchrotron XRD

Synchrotron X-ray diffraction (XRD) measurements were performed at the P21.2 Swedish Materials Science Beamline at Petra III, DESY, Hamburg. Using a high-resolution monochromator together with large area detectors and a micro-sized beam enabled to probe and map subtle changes in the steel subsurface, in terms of dislocation density and phase evolution. A significant number of measurements were performed within minutes, which would otherwise take days in a lab measurement. Whilst Ovako AB has contributed to the project by providing steel expertise, sample preparation, and complementary lab-scale investigations, Scatterin AB has been responsible for the synchrotron XRD measurements and data analysis using their dislocation density analysis code package as part of their proprietary software: Scatterin SaaS.

“Synchrotron XRD gave important microstructural information that will assist our development efforts in sustainable and more damage-tolerant bearing steel. We are very happy with the results from our collaboration with Scatterin and DESY.”

Steve Ooi, Group Technical Specialist – Ovako

“We have received excellent support from beamline scientists and the industrialization office. The Swedish Materials Science beamline enables high-quality data to be produced from our experiment. We hope to continue this collaboration in the future.”

Ahmet Bahadir Yildiz, CEO – Scatterin AB

Contact Partners

Case Details

Sactterin AB, Ovako AB

Scatterin ABSwedish Material Science Beamline P21