Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Identifying leaking syringes with neutrons

The biopharmaceutical company Sobi together with neutron experts from RISE used neutron radiography for the detection of leakages in prefilled syringes. The results show the potential of this technique in detecting leaks, with significant advantages for design and quality assurance in syringe production.

How to test leakages in syringes

Sobi (Swedish Orphan Biovitrum AB) is an international biopharmaceutical company specialised in rare diseases. Some of the company’s products are commercialised as prefilled syringes for self-injection of the pharmaceutical treatment. For Sobi, being able to certify the absence of leakages in prefilled syringes without compromising their integrity would be an important technological achievement. The implementation of such detection method would benefit production and quality assurance, while also help prevent the costly investigations that take place in cases of leakage. In this research project, Sobi successfully verified the benefits of using neutron radiography for the detection of leakage in prefilled syringes.

Look and do not touch

A leakage in a prefilled syringe occurs when a liquid in the syringe glass barrel enters the syringe needle and passes out to the interior of the protective needle shield. The product is still sterile, but the liquid will be seen as drops on the outside of the needle when opened or may clog the needle. When the liquid inside the needle evaporates, it leaves behind solid residues that block the needle or migrate into the rubber shield. The only way to assess the presence of a leakage in the rubber needle shield is to use a technique that can reliably detect and visualise a liquid inside the needle or needle shield without compromising the integrity of the syringe and its rubber shield. That’s no trivial task and, currently, the only way to achieve this is by using neutron radiography.

The exceptional neutron radiography

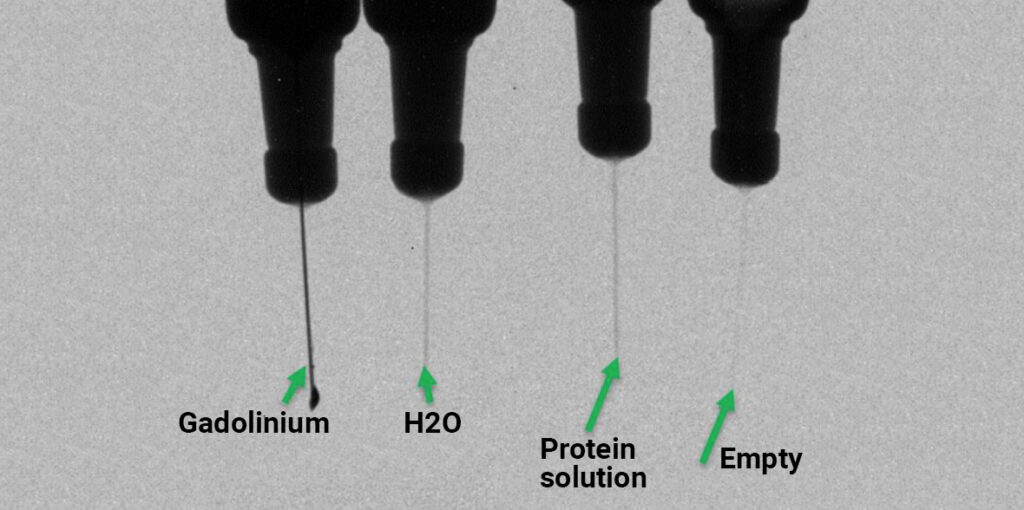

At the Laboratorie Leon Brillouin (LLB) in France, a team of representatives from Sobi and neutron experts from RISE and LLB tested the use of neutron radiography. Syringes with pre-attached needles were filled with three different aqueous solutions: pure water, a protein solution, and a solution containing gadolinium. Gadolinium was selected because of its excellent contrast with neutrons that makes it a suitable marker. The team then used neutron radiography to visualize the liquids through the steel needle.

The results were encouraging and confirmed that neutron radiology is a valuable and effective tool for the detection of liquids inside syringe needles. Furthermore, the researchers were able to achieve their goal by designing and developing a method to detect leakage in prefilled syringes without compromising the integrity of either the syringe or the needle shield. This is an important achievement that can help Sobi assessing issues in manufacturing and syringe design.

“It has been an exciting project to apply large-scale facilities to solve industrial challenges for biological products”

Jonas Fransson, Swedish Orphan Biovitrum

Video: Researchers Emanuel Larsson explains more

Emanuel Larsson, one of the RISE experts involved in the experiment, explains more about tomography and the research project. Swedish and English subtitles are available.

Contact Partners

Case Details

Swedish Orphan Biovitrum AB

LSRI-initiative at RISEExperimental Medical Science | Tomography – Emanuel Larsson