Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Improved packaging products using X-ray scattering techniques

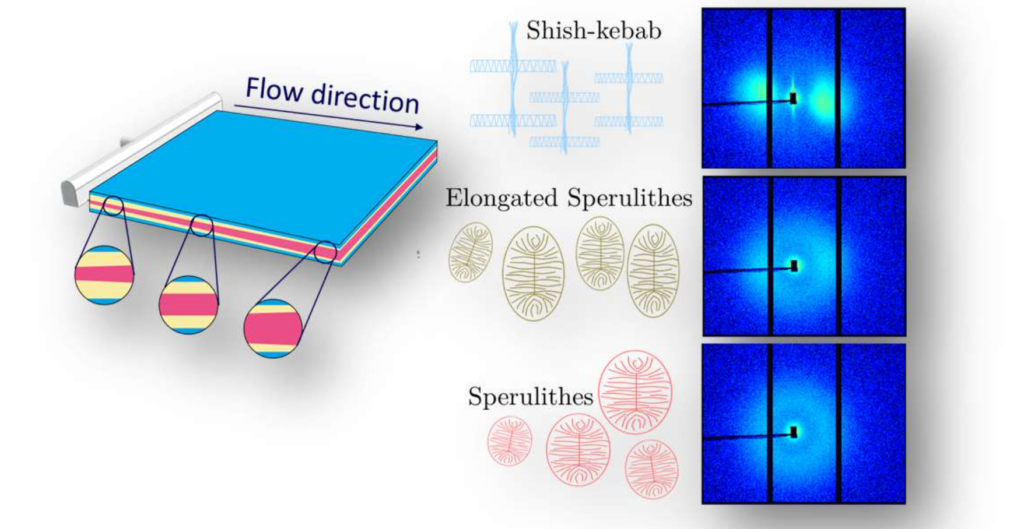

Most polymer-based packaging opening devices are produced by injection moulding. The packaging company Tetra Pak and Chalmers University have used small- and wide-angle X-ray scattering (SAXS/WAXS) to learn more about injection moulding processes and ultimately improve the properties and composition of the company’s opening devices.

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould. In this case, the material is a semicrystalline polymer.

When injected into the mould, the polymer forms a heterogeneous composition in the through-thickness direction of the produced material, a layered structure, where the thinnest layers are as thin as 0.01 mm.

X-ray scattering as an ideal technique for studying injection moulding processes

Synchrotron-based SAXS/WAXS scanning is an ideal technique to gain more knowledge about injection moulding processes by revealing information about the number of layers and their individual thickness and composition.

This information is impossible to obtain with laboratory X-ray equipment since the X-ray beam would be much too wide to resolve the thin layers. Researchers at Tetra Pak have previously used polarised optical light microscopy to visualise the layers.

However, this method prevents the study of pigmented samples, and it also doesn’t provide any information about the crystalline microstructure.

Shish-kebab structures and spherulites uncovered

The researchers from Tetra Pak and Chalmers University used the cSAXS beamline at the Swiss Light Source at the Paul Scherrer Institute in Switzerland to perform their experiments. The experiment was performed remotely due to the corona pandemic in 2020/2021.

Samples produced with different injection moulding settings were evaluated in the experiment, and the results show that it is possible to detect sample layers, thickness, and microstructures.

A shish-kebab structure is found in the outer layers (blue), followed by elongated spherulites (yellow) and symmetrical spherulites in the centre (pink). Source: Tetra Pak/The cSAXS beamline X12SA at the Swiss Light Source, Paul Scherrer Institute (PSI).

A step towards improved packaging products

The collaboration has shed more light on how process settings can impact the microstructure of the material during injection moulding, ultimately leading on to improved and better performing products.

In addition, the experiment made use of an easy-to-use workflow, with optimised data collection and data visualisation to enable Tetra Pak to perform similar types of experiments independently in the future.

“This collaboration with Chalmers has increased our awareness, knowledge, and potential of advanced experimental techniques that will become available soon at MAX IV near Tetra Pak in Lund.”

Johan Elgebrant, Manager Injection Moulding, Tetra Pak

Contact Partners

Case Details

Tetra Pak

Chalmers Industriteknik