Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Looking inside a Battery

Together with the industry partner FINDEN LTD, DESY scientist used x-ray diffraction computer TomographyA non-destructive technique used for constructing three-dimensional images from two-dimensional projections to characterise the internal structures of materials.More info (XRDUsed for atomic structure determination of materials, e.g. pharmaceuticals, catalysts, battery materials, and proteins.More info-CT) to gather insights into the inner life of simple AAA batteries to reveal their aging process and in order to make these last longer.

Using diffraction for contrast

But, how can we make them to last longer? A look inside the batteries might get us a step closer to understand mechanisms behind degradation, capacity loss or charging. Another important aspect is the possibility to study batteries in different charging levels and examine the dynamics inside the battery during use. But most experimental techniques lack physicochemical insights. Imaging the batteries with synchrotron radiation x-ray computed Tomography (SR-μCT), a standard 3D non-invasive imaging technique, is nearly impossible, because the image contrast is produced by element specific x-ray absorption, which is low for most chemicals inside batteries. A way to bypass this, is by using x-ray diffraction computer Tomography (XRD-CT). This technique does not rely on the absorption of incident x-rays, but on the electron density of the sample. Synchrotron x-ray diffraction can then be used to investigate samples with low x-ray absorption materials as one find in a battery.

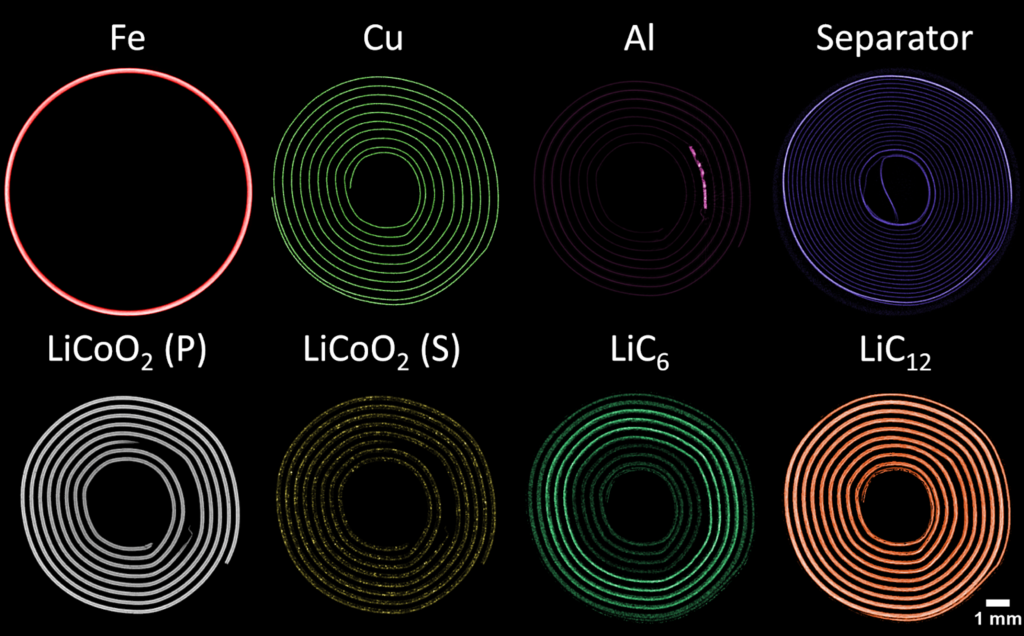

Colorful Spirals of Elements and Compounds

XRD-CT proved to be a great extension for standard x-ray CT as it delivered information of chemical composition with micrometer spatial resolution and revealing unwanted phases and non-uniform phases distribution. XRD-CT can be applied to real life battery and other devices, making it extremely useful for industrial clients with specific needs and problems. This method can be applied under time resolved conditions, to examine phases transformation inside a battery while charging or discharging the battery. Another interesting aspect is the imaging of the ageing process, to observe mechanical damage on the structure and link it to their starting points at the micrometer scale, by scanning the battery after various amounts of charging cycles. Also, XRD-CT showed its possibilities in depth resolution, which is very important for industry clients that want to do research on actual devices they are aiming to improve. With the ultra-high spatial resolution of synchrotron radiation XRD-CT provided by PETRA III is ready to help industrial clients on their way to understand reasons for battery ageing, reduced capacities and slow charge cycles.

Contact Partners

Case Details

Finden Ltd., DESY

Finden LtdP07 – High Energy Materials Science Beamline (HEMS)