Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Complex ores meet synchrotron light

The company Boliden and Luleå University of Technology used X-rays at MAX IV to understand how to improve the extraction of by-products from complex ores. By-products obtained from ores have an increasing value in many industrial areas including renewable energies.

The importance of by-products

Boliden is a Swedish high-tech metal company with 90-years expertise and its own mines and smelters. Further to the main metals retrieved from its mines, Boliden invests in the extraction of other metallic and non-metallic elements often found in complex ores. Such by-products are identified through trace element characterisation. As the market value of ore by-products increases, their extraction becomes common practice. Therefore, efficient identification of all elements included in ores becomes ever more meaningful for Boliden and the rest of the global mining industry.

Boliden joined forces with ore geological experts at the Luleå University of Technology and came to the NanoMAX beamline to optimise the analytical procedure for planning localisation and extraction of elements from complex ores. This project shows how synchrotron light can bring crucial added value to routine analysis in mining operations by improving the efficiency of extraction of ore by-products.

A helping hand for renewable energies

The use of metallic and non-metallic by-products from complex ores is of ever-higher importance in many industry sectors, with one noteworthy example being in the renewable energy industry for the production of solar panels and wind turbines. These elements typically occur in small concentrations and often irregularly distributed in the ore. To be able to optimise the recovery of these by-products, it is crucial to improve the analytical procedures used in the planning of metal extraction from mining.

Sparking new ideas

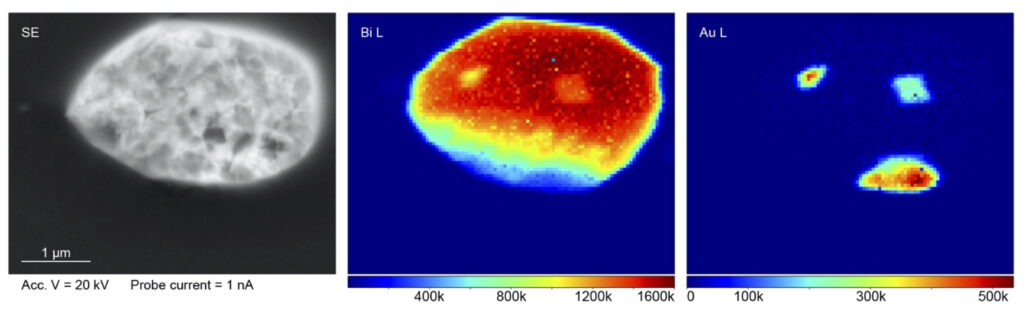

The use of synchrotron-based X-ray opens the way for more advanced observations compared to current analytical routines used by the mining industry. Using Nano-XRF (nano X-ray fluorescence imaging) available at MAX IV, researchers can create detailed maps of the composition and distribution of different elements inside the ore samples. The jump in resolution from micrometres (one-millionth of a meter) to nanometres (one-billionth of a meter) made possible by MAX IV X-rays is of crucial importance, unlocking new opportunities for the studies of ore geology and mineral processing.

“We aimed at finding out where in the ore sample the metals that are of interest for renewable energy are located. Finding this out, it is then possible to develop mineral processing schemes for an optimised extraction of these metals.”

Glenn Bark, Luleå University of Technology

The collaboration of companies like Boliden with academic actors such as the Luleå University of Technology and facilities like MAX IV is beneficial for all parties. Thanks to the experience acquired in this project, researchers gained valuable skills regarding the synchrotron-based analysis. They can now confidently apply the acquired knowledge to investigate new ideas and projects that will use synchrotron-based techniques as a way of generating important scientific data.

Header image: A view of Boliden’s Aitik open pit mine. Photo: Stefan Berg; source: boliden.com

Contact Partners

Case Details

Boliden AB

NanoMAXOre geological expertise – LTU