Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

A nano-scale glimpse into stainless steel brazing

Alfa Laval and Lund University used MAX IV to gain insights into the deoxidation process that occurs during the brazing of stainless steel products. These observations can help Alfa Laval to optimize its production process and solve R&D challenges.

A leader in stainless steel products

The Lund-based company Alfa Laval is an industry leader in the manufacturing of stainless steel products such as heat exchangers used for tap water heating and in air conditioning systems. To stay ahead of the competition, the company takes advantage of MAX IV Laboratory and its brilliant X-rays. Using the unique microscopes and techniques available at MAX IV, Alfa Laval’s engineers acquire new and strategical insights that can help the company improving its products and production processes.

Deoxidation and brazing

In this study, researchers from Alfa Laval and Lund University used MAXPEEM, one of the microscopy beamlines at MAX IV, to observe the deoxidation process that occurs in brazing. Deoxidation is a step of crucial importance in the production of heat exchangers, where the high brazing temperatures help to remove the thin layer of oxide that covers the surface of stainless steel alloys. Once the oxide layer is removed, the braze material wets the steel surface and creates a sound joint. Gaining new knowledge on how the oxide layer is removed during brazing can allow Alfa Laval to optimize its production process and solve R&D challenges, thus improving time and resources allocation.’

“A black box opener”

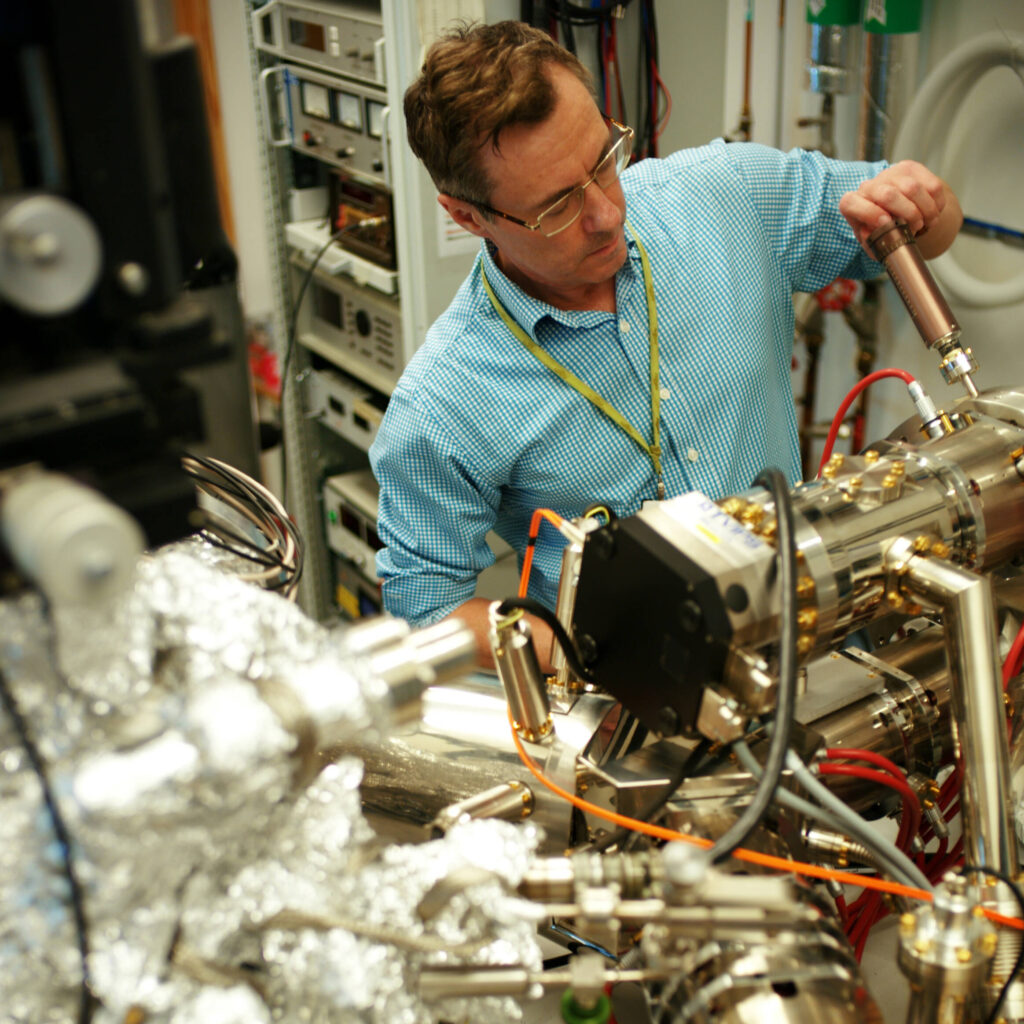

Since the oxide layer is only a few nanometers (a billionth of a meter) thin, observing how it is removed is no trivial task. This is why Alfa Laval needs a special microscope. Using synchrotron X-rays at MAX IV, researchers from the Swedish company were able to observe the deoxidation process at an unprecedented resolution and at the actual brazing temperatures (above 1000°C), hence mimicking the production conditions. Such advanced experiments at extreme vacuum and temperature conditions can be performed only by a handful of microscopes in the world, and the Spectroscopic Photo Electron and Low Energy Electron Microscope (SPELEEM) installed at MAXPEEM is one of them.

”The experiment is a black box opener which generates knowledge about what occurs during industrial-scale brazing.”

Jenny Rehn Velut, Manager Alfa Laval R&D Materials Technology & Chemistry, Lund

After this project, Alfa Laval has established a recurring and fruitful collaboration with Lund University and MAX IV, returning to the facility for follow-up investigations, as well as starting new and different research projects.

The experiment is a black box opener which generates knowledge about what occurs during industrial-scale brazing.

Contact Partners

Case Details

Alfa Laval

MAXPEEMNanoLundProduction and Materials Engineering – LTH