Send us your feedback

Here you can send us feedback on the Maxess-website. Please describe the problem or what’s missing in a clear way, and on what page you found the issue. Thank you so much for your help!

Better and sustainable protective textiles for the healthcare sector

OHB System AG, a subsidiary of European space and technology group OHB SE, has conducted a study to examine the protective effect of cleanroom clothing commonly used in cleanrooms for satellite production against surface interaction with potentially infectious droplets. The results from industrial research show as well the potential for quality control, further textile optimization and indicators for aging for example through washing.

What satellites and medical staff have in common

In this case study OHB Systems AG cooperated with Dastex Reinraumzubehör GmbH & Co. KG, Krüss GmbH, DESY, Helmholtz Center Hereon, Volume Graphics GmbH and Quality Analysis GmbH to study the repellent effect of polytetrafluoroethylene (PTFE) treated textiles. Such textiles are commonly used in in cleanrooms for satellite production. Satellites are manufactured in a strictly controlled environment that may only be entered in special protective clothing to prevent contamination of sensitive components by humans. In view of the global coronavirus pandemic and the resulting shortage of suitable protective clothing for medical and nursing staff as well for caregivers in particular, the before-mentioned partners have been working together to investigate whether reusable, PTFE treated cleanroom clothing is also suitable for protecting frontline workers from harmful influences and especially from infectious droplets cross contamination.

Validating the protectiveness with Tomography data

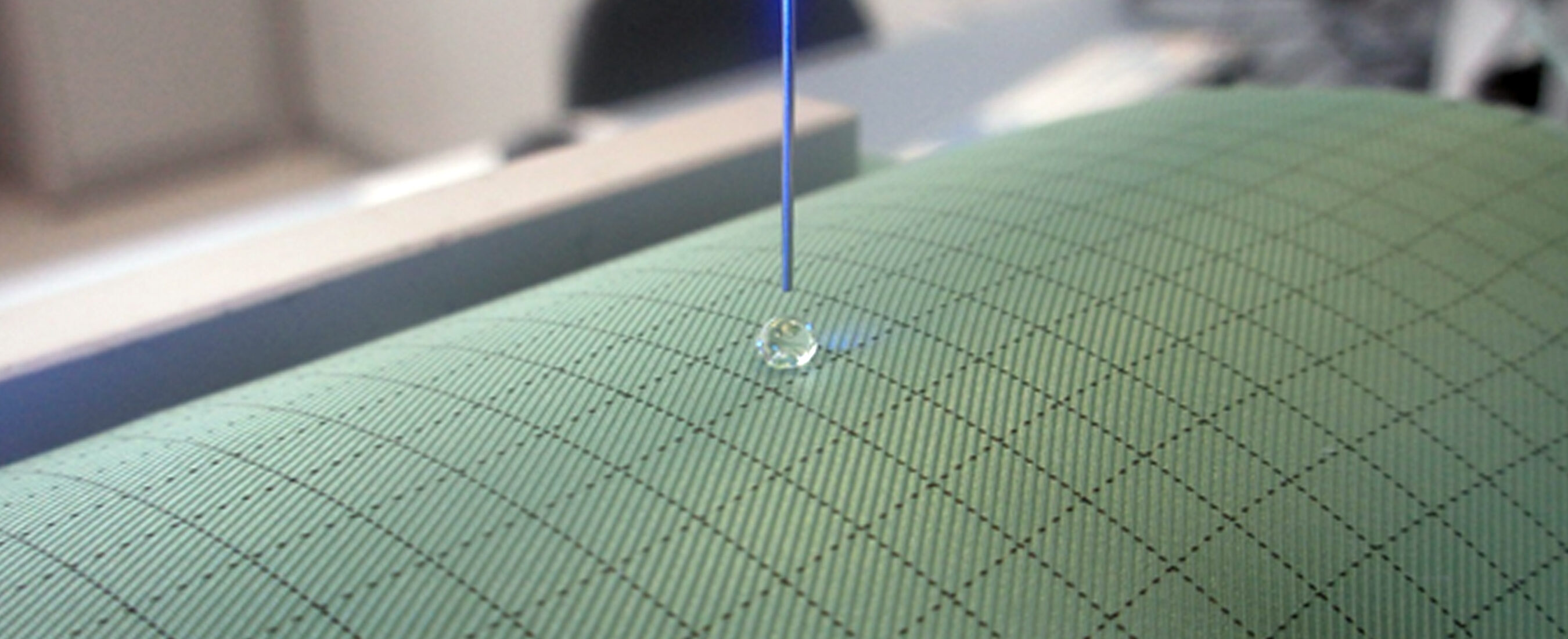

In order to show that cleanroom clothing offers protection against droplet infection and does not lose its protective properties even after 120 washing cycles, it was investigated how droplets emitted by humans behave on different textile surfaces. As a substitute for real saliva drops, droplets of ultrapure water of appropriate size (100 µm) were used. These were applied to the different textile surfaces within controlled lab conditions at the synchrotron light source PETRA III at DESY. Here the scientists from the Helmholtz Center Hereon beamline P05 contributed to the measurement with high resolution computer Tomography images. By the means of the non-destructive, brilliant beam the textile structure became visible. This is essential for the data interpretation and subsequent optimization. The high-resolution computer tomographic data can validate even small droplets diffusing in and through the tissue samples.

Benefits of this new kind of protective clothing

While normal cleanroom clothing is not water-repellent, the measurements showed that cleanroom clothing finished with PTFE can keep up with commercially available disposable protective clothing in terms of its water-repellent properties – not only when new, but also shows no measurable degradation even after 120 wash cycles. The drops remain spherical on the textile surface at a contact angle of 140° and hardly adhere to it, which speaks for a good protective effect. Contact angles can be measured relative easily, but the insights gained at the synchrotron facility PETRA III are mandatory for a deeper understanding of the parameters influencing the contact angle. To sum it up, this case study helped to establish contact angle measurements as pass fail criteria for product selection at purchase, quality or service laundry level. And Modified cleanroom clothing can be an alternative to disposable protective clothing, not only for clean room research and production, but also for healthcare workers.

Contact Partners

Case Details

OHB System AG, Dastex Reinraumzubehör GmbH & Co. KG, Krüss GmbH, DESY, Helmholtz Center Hereon, Volume Graphics GmbH, Quality Analysis GmbH

P05 – Imaging Beamline (IBL)GEMS